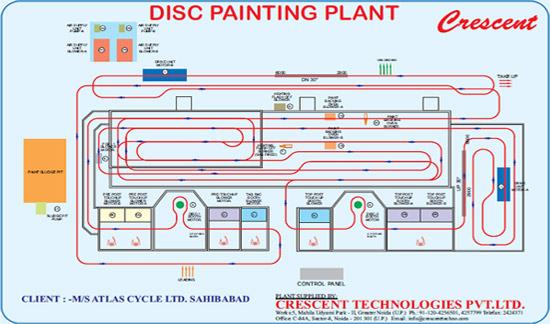

Automatic Disc Applicator

Crescent offers high RPM’s Electrostatic Discs for Automatic Paint Applications. The Electrostatic disc tends to throw the paint away when the paint passes through the charged disc, forming much finer thin fog. The lost paints are sucked back to the work piece due to electrostatic effect and the over spraying phenomenon is thus minimized.

Applications : Bicycle Parts, Computer Cabinets, Wooden items, small tubular components and manymore…..

|

|

Automatic Bell Applicator

Crescent also provides automatic bell applicators. Here the paint is fed to bell shaped applicator rotating at high speed. The paint particles are atomized due to high rotation speed and are negatively charged up-to 100kV. The Bell Applicators gives very high Transfer efficiency which may reach upto 90% and also provides high surface finish of the Painted Surface mainly used for Automotive industries.

Crescent also provides automatic bell applicators. Here the paint is fed to bell shaped applicator rotating at high speed. The paint particles are atomized due to high rotation speed and are negatively charged up-to 100kV. The Bell Applicators gives very high Transfer efficiency which may reach upto 90% and also provides high surface finish of the Painted Surface mainly used for Automotive industries.

Painting Robots Automation

Crescent also supplies Plants integrated with Painting Robots. Robotic painting / coating produces top quality results. Once properly programmed, an industrial painting robot can apply paint material without leaving behind any drips, inconsistencies, overspray, etc. Paint and/or coating are applied precisely and consistently. This results in improved quality, enhanced productivity and no skilled manpower.

Beside painting robot, material handling / transfer robots can also be provided.

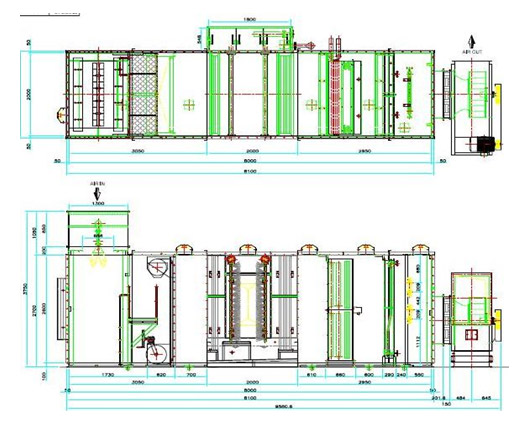

Air Supply/Make up Unit

Air Supply unit to positively pressurize the Spray Painting Booth will make an integral part of paint shop. At Crescent we integrate the ASU as per the actual requirement of paint shop and site conditions. ASU would resistant entry of dust inside the paint shop area specially paint booths and offer operator comfort with air filtration down to 5 micron filtration level after series of pre and fine filters.

Types / Salient Features :

- Dry filtration without water, specially for powder coating applications.

- Wet type with spray nozzles water washer system for high capacity.

- Wet type with Celldek media

- SS/PVC mist eliminators for complete moisture removal

- Interlocking for humidity control

- VFD for motor speed variation, consequently capacity- Energy Savings.

- Maintenance facilities

- Double Skin Puff Panels to give better thermal /noise insulation.

Optional Features :

- Heating by Heaters/Burners- for Winters.

- Cooling (Air conditioning) by chiller

- Air temperature and humidity control for sustained atmosphere inside the paint booth.